Aerospace Parts

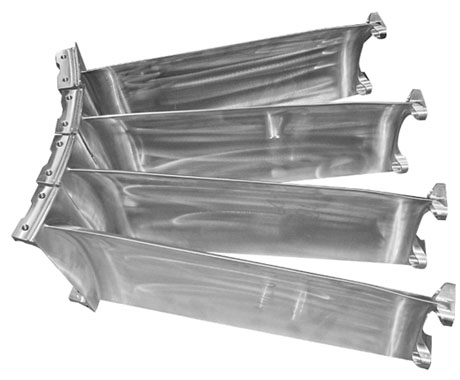

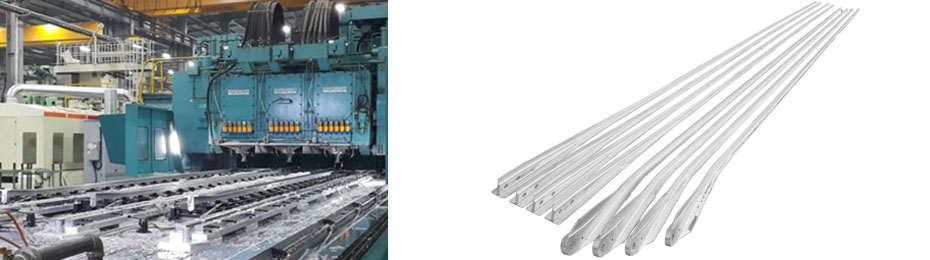

- Wing stringers

Center of excellence for Wing bottom panel stringers

A320 Series(full rate) Wing bottom panel stringer

- Material : Al Ext, 2026-T3511 , 1.2m~16.0m Long

- Production rate : 1200 pcs/mon (Current)

⇒ 1500 pcs/mon (Sancheong Feb. 2017)

⇒ 2500 pcs/mon (Sancheong Max capa)

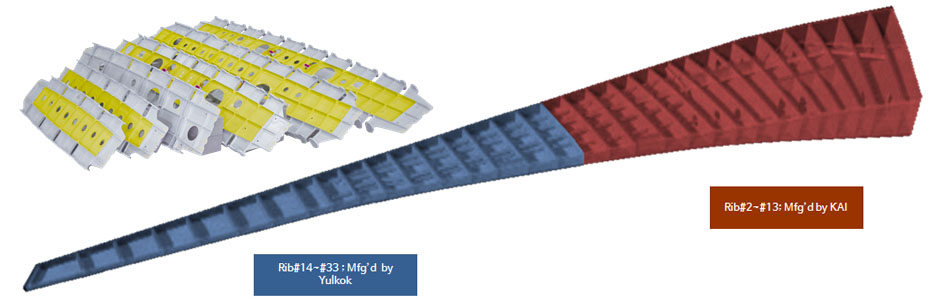

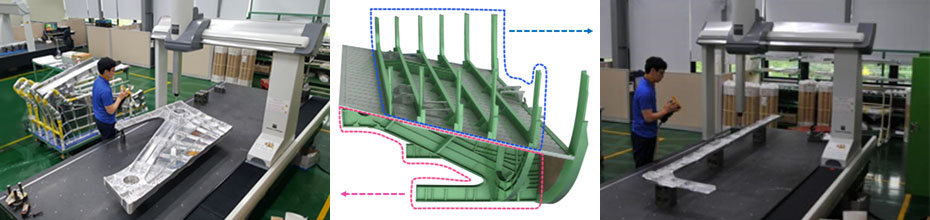

Center of excellence for wing ribs

A350 Wing-Rib RSP program between Airbus & KAI

- Material : Al alloy (Al7050-T7451 plate)

- Material Size (Rib #16) : 130 x 655 x 2,995mm

- Material Weight 714kg → Part weight 18kg

- Yulkok had participated from design phase

B777 Fixed Leading Edge Ribs

- Material : AL Plate, AL7050T7351

- # of Detail Parts : 138 Items, Tight Tolerance Parts → Hole size .0005in & True Position .002in

B787 Flap Support Ribs

- Material : AL Plate, AL7050T7351

- # of Detail Parts : 130 Items, Tight Tolerance Parts → Hole size .0007in & True Position.014in

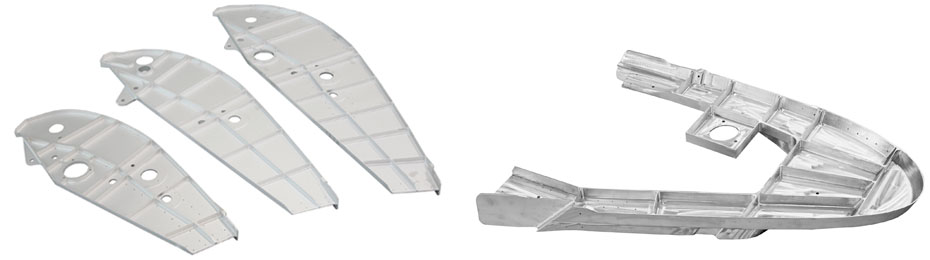

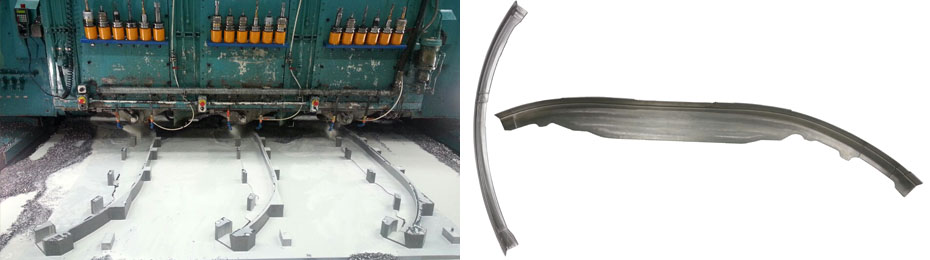

Machining of complicated spar chord

B737 Empennage Spar Chords

- Material : Al Ext, 7150-T77511 , 120″~300″ Long

- Process : Hot Forming → Machining → Incremental Forming → Inspection

- Heavy detail parts

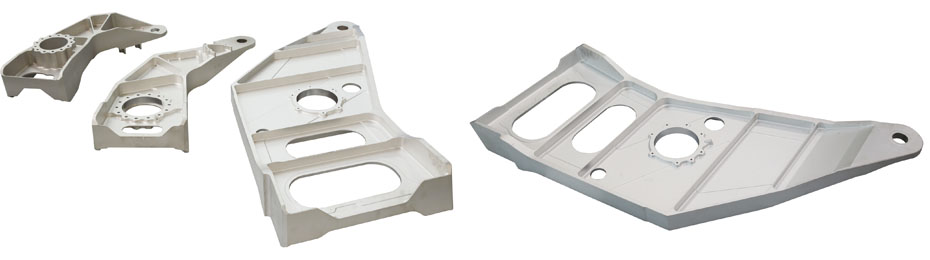

High speed machining of Heavy Structure

A350 NLG Bay Lateral Panel & Gantry

- Material : Al-Li, Al2050-T84, t160 X 1,400 X 3,790(mm)

- Equipment : DST ECOSPEED F1040(Max 30,000 RPM, Max Feed rate 20 m/min)

Machining of complicated process

B787 MLG Beam

- Material : Al Forging, 7085-T7452, t315 X 710 X 4,230(mm)

- Titanium Parts

Machining of Hard metal - Titanium

P-8A Ti-Spar & Fitting

- Material : Ti Ext. Ti-6AL-4V , 3,430~3,940Long(mm)

B787 Pivot Bulkhead Titanium parts

Extensive experiences of hard metal machining for 25 years

T-50 wing attach fitting (Ti)

B737 Y-Fitting (Ti)

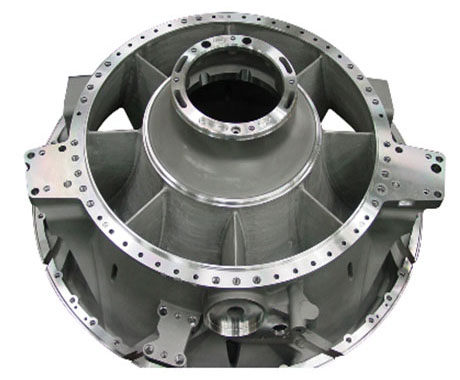

- Engine parts

Machining of Engine Component - Ni Alloy (Inconel 718, 783, 909)

CF34 FWD case

Genx STK ring

F100 Case

GE Leap case

Launch vehicle case

Machining of Engine Component - Al

CF34 Al Front case

GE90 Al Outlet guide vane